Shock Finder™

Classic techniques of vibration analysis, based on the frequency domain, have shown their limit mainly for 2 reasons:

- for variable speed machines, where measurement needs to be done in stable conditions

- and for low speed rotating parts, where faults can result in very low energy phenomenon and are hardly detectable…

ONEPROD has developed in 2008 and based on real industrial application, a specific indicator analyzing the time domain – to get variation-free indication – in order to detect automatically abnormal shock phenomenon on low speed and variable speed machines: the ONEPROD Shock Finder™.

To learn more about ONEPROD methodology for monitoring variable and low speed machines, please read our white paper online!

Features

Reliable shock detection

With ONEPROD Shock Finder™, the fault detection is automatic, even on low speed components such as low speed parts of gearboxes:

- it is not sensitive to random shocks that may result from impulsive and not repetitive phenomenon. Only shocks maintained over the time can trigger an alarm.

- as the algorithm is processed in the time domain, it is not affected by the variable process conditions (speed, load…)

- it offers reliable detection in the low frequency domain (gears) even for the detection of low energy phenomenon hidden in the overall vibration of the machine

Foolproof setup

With absolutely no setup needed, the Shock Finder™ automatically removes all “normal” vibrations of the machine which are not resulting from impulsive shocks, counts the shocks filtered, and provides smooth alarming over the time.

It avoids missing phenomenon due to improper filtering settings and makes it reliable to use by anyone.

Easy decision making

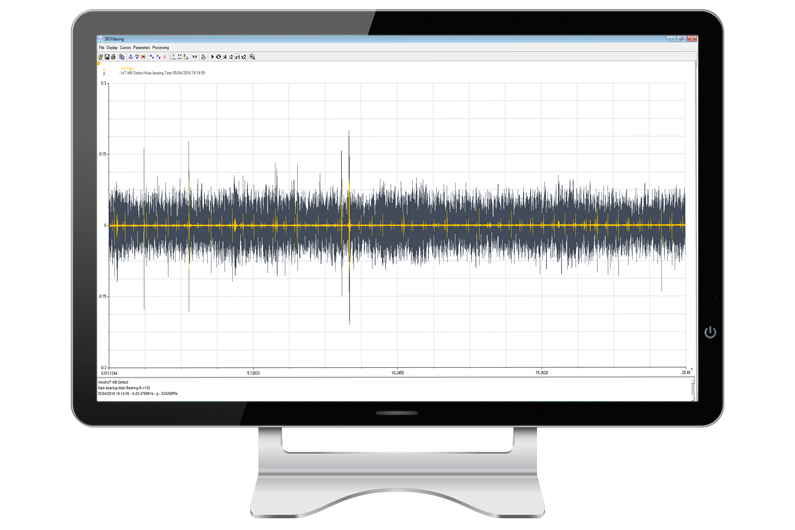

The results provided by the Shock Finder are:

- binary information on the presence of abnormal shocks (Green / Yellow indicator), warning the vibration analyst of the presence of shocks

- the number of shocks detected

- the filtered signal to determine the origins of the shock phenomenon automatically detected

The ONEPROD Shock Finder™ allows detecting bearing and gear defects at fairly early stage, and can be used as good complement to classic techniques: Some defects may only be detected by the Shock Finder™, and it can also confirm the results shown by other indicators and make the decision process easier on the diagnostic of critical machinery.

Cost effective monitoring

The use of the Shock Finder™ helps reducing the number of sensors needed and the cost of condition monitoring of critical machines. The benefits are:

- the use of standard accelerometer even for the monitoring of low speed components

- the monitoring of unbalance phenomena and ball bearing defect with a single accelerometer

No need for phase measurement with a tachometer thanks to the analysis in the time domain