Key points

- dustproof and waterproof IP51 : no cabinet needed

- size: 371 x 175 x 133 mm (14.6 x 6.89 x 5.23 in)

- easy DIN Rail mounting

- built-in Shock Finder™ algorithm for the detection of abnormal shocks on low speed components

- proven monitoring methodology for the management of variable operating conditions

- compatible to the latest applicable EMC standard

- insensitive to the wind turbine electromagnetic disturbances

- resistant to lightning impact

- 12 Analog channels for vibration or process information

- extended capacity with numerical inputs

Features

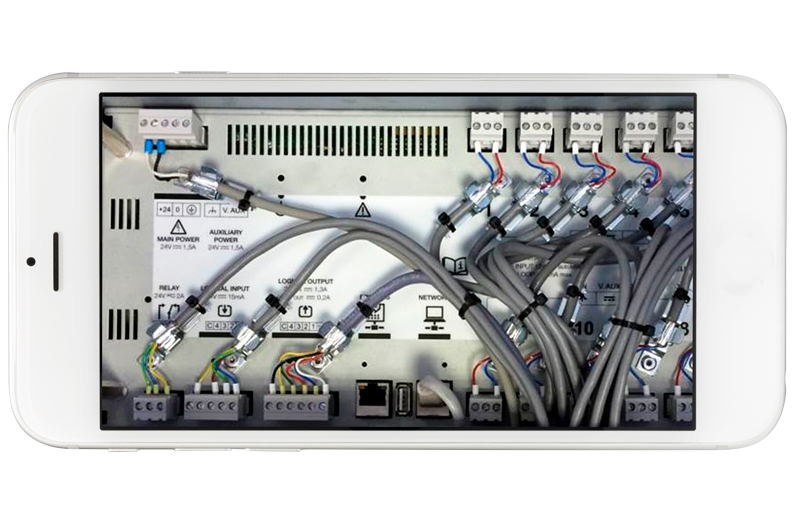

Easy installation

Compact, waterproof and dustproof to grade IP51, ONEPROD KITE can be installed in the nacelle without any enclosure. KITE can be easily mounted on a DIN-rail. Visual assistance is marked on the product to provide quick and reliable cabling.

Designed for the wind industry

Compliant with the latest ECM requirements, KITE is resistant to lightening impacts and to the electromagnetic disturbances of the wind turbine. Measurements are reliable, thus enabling accurate monitoring of the wind turbine. With no fan and no conventional spinning hard-drive, KITE’s design makes it reliable for long-term operations.

Comprehensive monitoring of the core components

ONEPROD KITE offers 12 data acquisition channels. All information needed for relevant monitoring of the drivetrain and nacelle can be connected to KITE: accelerometer, tachometer, and 4-20 mA or DC inputs for process information. In addition, parameters available in the PLC, such as wind speed, power, pitch, yaw, temperature, can be collected without any extra channel in numerical format.

Reliable monitoring of low-speed parts

ONEPROD KITE offers early fault detection capabilities on the low-speed rotating parts of the wind turbine, thanks to a unique set of tools designed for analysis in the time domain:

- automatic shock detection with the Shock Finder™ algorithm (presence and number of shocks)

- band-Kurtosis providing smooth alarming

- various post-processing tools, such as filters and statistical indicators

- acquisition is performed synchronously on all channels, providing easier analysis and better diagnosis capabilities.

Assistance to decision-making

The latest diagnostics and maintenance recommendations are available in real time and from anywhere worldwide in the ONEPROD NEST software.

It makes it easy to optimize the maintenance process:

- better spare parts management

- pooling of replacement operations

- removing systematic maintenance controls and their related costs