The implementation of a planned maintenance program (often called predictive maintenance) always raises the question about which monitoring methods to use. If you find yourself at this stage, this article will help inform you about vibration analysis, its advantages and how it can help you generate gains faster.

Anticipation

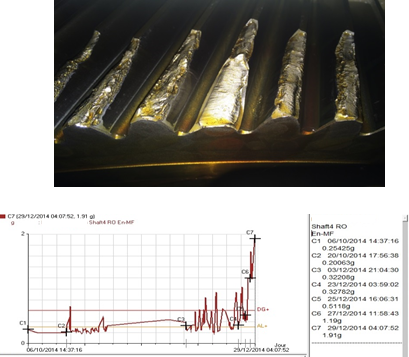

First of all, let’s remember that the objective of a predictive maintenance program is to anticipate the degradation of a machine’s functionality in order to schedule appropriate repair work. This is the logic of a condition monitoring program based on the extrapolation of a behavioral trend. The anticipation will be all the more effective in that the method chosen will be able to identify weak signals (detection at the earliest stage possible) and to reduce the time interval between two measurements (establishment of real trend lines). This is exactly what vibration analysis allows. A vibration spectrum contains ‘rich’ data in which it is possible to read extremely tenuous defects, such as a spalled ball bearing. This rich data is acquired just as easily as simple data, like temperature, without intruding or shutting down a machine (in an automated manner where necessary) and with the desired measurement frequency.

Diagnostics

The other advantage of the rich vibration spectrum is its ability to explain a worrying behavior. Vibration analysis not only provides alerts, but is also able to provide a real diagnosis to guide maintenance work. This is one of the reasons why it has been used for in years in the monitoring of critical machines in heavy-duty industries where technicians have to completely understand what is happening within a machine before even opening it.

Versatility

The advantages of vibration analysis don’t stop there. This method applies to all components which undergo significant efforts and are also the most likely to breakdown. Vibration analysis enables the detection of all the common defaults found in rotating machines: unbalance, lineage, bearing, gear, sets and cavitation. It is extremely versatile and can adapt to a high number of machines in a factory. It is a good way to reduce, with a single tool, the frequency index and the probability of missing a breakdown detection. Plus, seeing as the defects will be identified earlier on, the severity index will also significantly decrease.

Other monitoring methods, such as thermal analysis, oil analysis, and electrical analysis also have their advantages and can be very relevant and complementary when dealing with a targeted problem. Although, none of them, in our opinion, provide both early detection of numerous defects and a reliable explanation for these defects.

Vibration analysis may seem difficult to grasp or restricted to specialists only. Fortunately, this is becoming less and less true. Today, artificial intelligence offers extremely reliable diagnostic tools, like the ONEPROD Accurex, which can be used by general maintenance technicians. Feel free to come and discuss it with us. You will see everything you have to gain by following the vibrations of your machines!

The connected mechanic: already a reality?

Today, maintenance mechanics are at the forefront of digitalizing factories. Today, maintenance mechanics are at the forefront of digitalizing factories. Improved monitoring of equipment as well as breakdown prevention and reduced repair work time [...]

Vibration Analysis Basics – Time waveform acquisition

Collecting a correct time waveform Time waveform in vibration measurement technology is basically known as “raw signal” as it represents a real information from the machine about forces being generated. As a first step [...]

Predictive maintenance: Wireless, a game changer

Bye, bye cables and connections, hello radio antennas. Wireless systems have brought communication technology to the next level and open up exciting new possibilities. However, attention to the details of how wireless systems carry out [...]

Leave A Comment