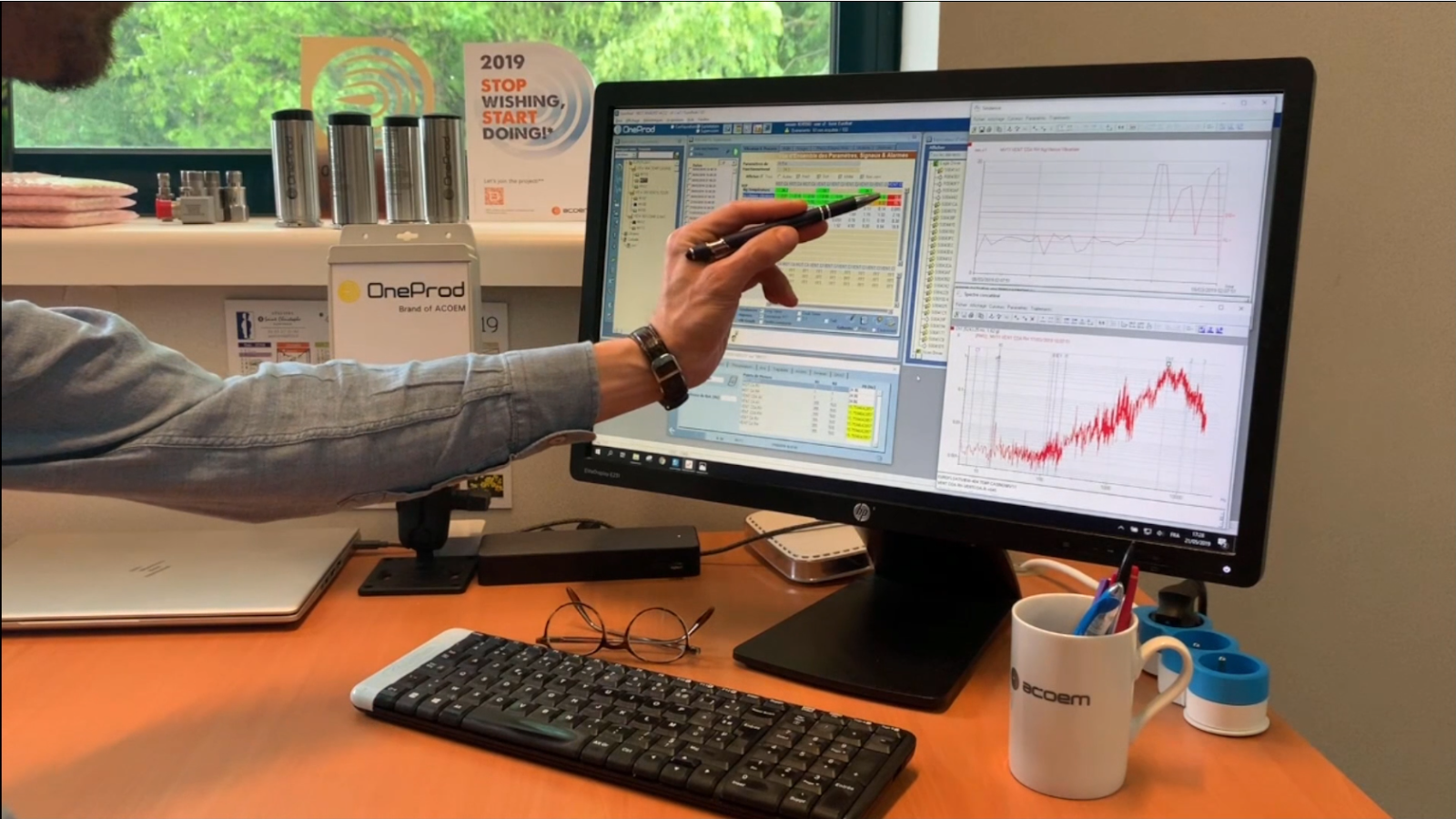

ONEPROD: your blog about industry 4.0 and conditional maintenance

Our experienced editors regularly suggest articles related to the world of IOT, connected objects, big data and maintenance. Follow our experts and discover methods, best practices and examples related to data and project management within the industry!

Together, let’s build the world of tomorrow.

Predictive maintenance: forecast, anticipate or predict?

What really does the term “predictive maintenance” mean? Should we really seek to forecast the date on which a machine or part will malfunction? Is this entirely possible? As scientists and specialists in vibration [...]

Wireless monitoring: track more equipment at a lower cost

Vibration monitoring has existed for years, and over the years we have been constrained to connect various sensors placed on a machine to a network using tens or even hundreds of meters of cables, [...]

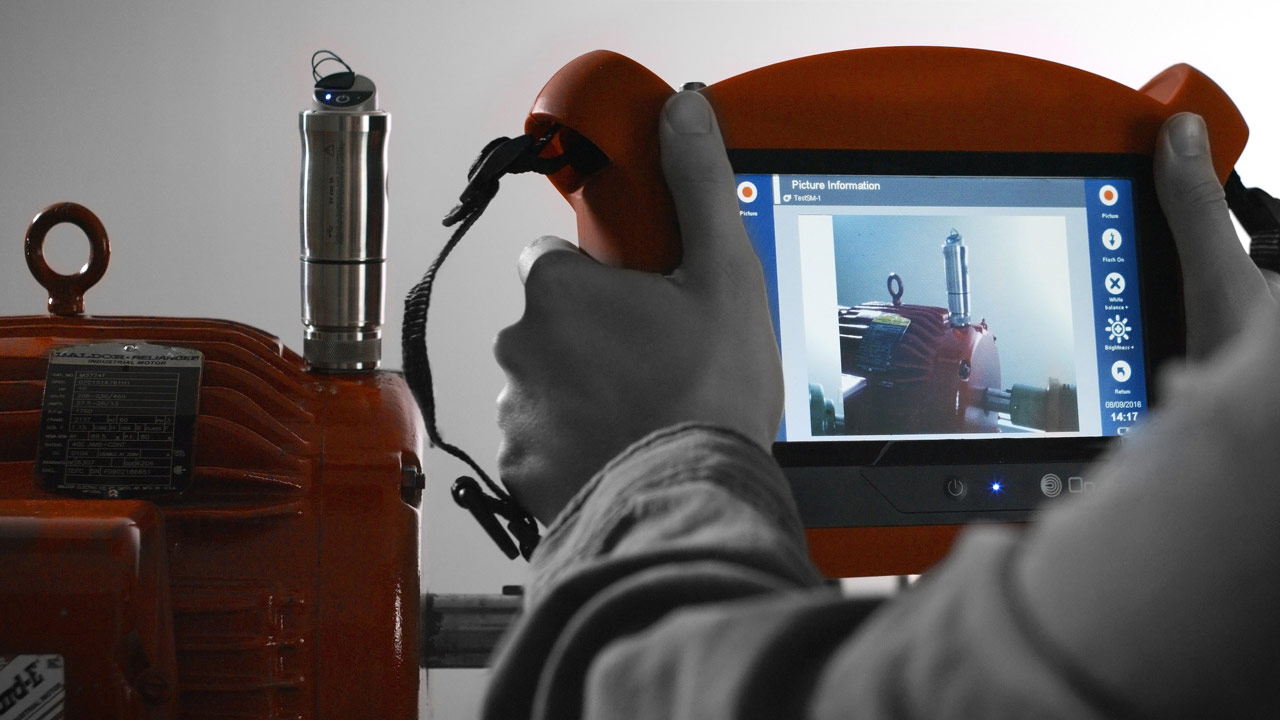

Vibration Analysis Basics – Sensor Mounting

Select the right mounting methodology As seen in our previous article, the settings of vibration measurement are crucial if you want to achieve the right detection and diagnostic performances. But, this is not the [...]

Maintenance 4.0 of rotating machines: what are the benefits?

Vibration analysis offers a lot of information to help understand the functionality and the overall health of rotating machines. As we explained in a previous article, if vibration analysis is widely used, especially in [...]

How does artificial intelligence improve vibration analysis?

The term ‘artificial intelligence’ (AI) encompasses all the computerized technology which allows a computer to imitate the human brain’s extremely elaborate analytical processes. This technology includes all the learning techniques (machine learning) and in [...]

Predictive Maintenance: Which KPIs to choose for vibration analysis?

Are you planning to set up a Predictive Maintenance Program but still not sure about which monitoring method to use? Or have you already opted for Vibration analysis and are wondering what indicators to [...]

Predictive maintenance: why choose vibration analysis?

The implementation of a planned maintenance program (often called predictive maintenance) always raises the question about which monitoring methods to use. If you find yourself at this stage, this article will help inform you [...]

Monitoring gearboxes: How to determine the location of sensors?

Vibration monitoring of a gearbox is an application with which we are regularly involved. Gearboxes are critical components in many industries. They are extremely solicited and can be very costly if they malfunction. They [...]

ISO10816 vibration velocity: an insufficient indicator for effective predictive maintenance

Vibration velocity is the basic indicator used to diagnose the health of rotating machineries. Alert thresholds for each type of rotating equipment in ISO standard 10816 were in fact established based on the vibration [...]

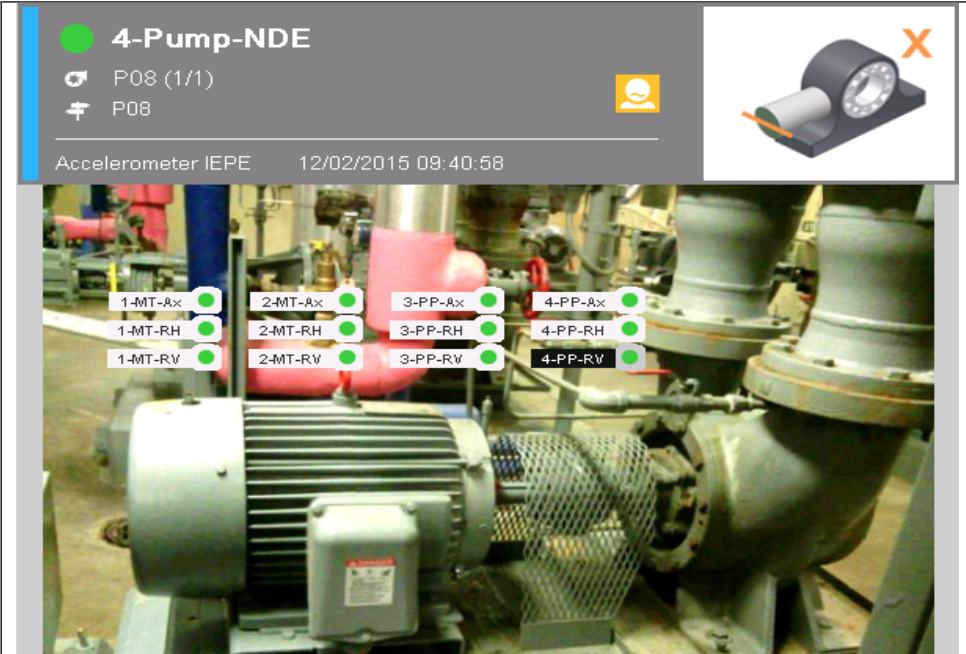

New strategies for data acquisition

In the first segment of this series of articles, we mentioned the main interest behind wireless vibration monitoring solutions: to integrate, at a lower cost, more equipment into planned maintenance. Going wireless multiplies the [...]